MATERIALS

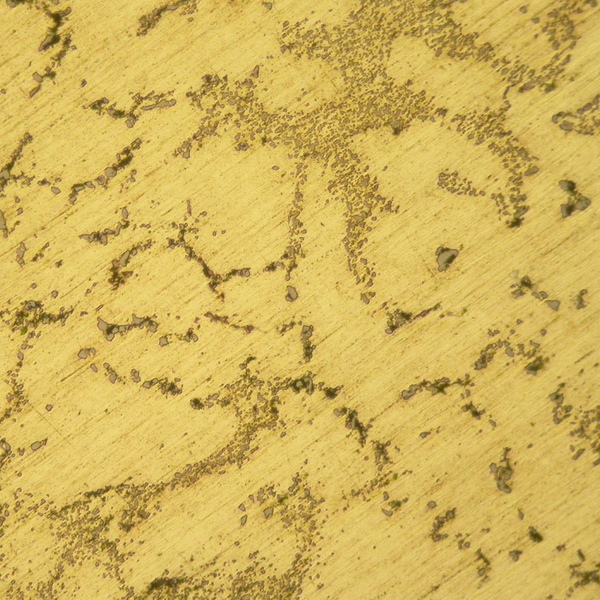

We produce castings of eight basic types of aluminium alloys AlSi10MgMn, AlSi10Mg (Cu), AlSi8Cu3, AlSi7Mg0.3, AlSi12, AlSi12 (Cu), AlMg5Si1Mn and AlCu5NiCoMnSbZrTi (RR350). Alloys AlSi10MgMn, AlSi7Mg0.3 and RR350 can be heat treated to improve mechanical properties. We provide heat treatment in cooperation with certified external companies.

| Materials |

|---|

| AlSi10MgMn |

| AlSi10Mg (Cu) |

| AlSi8Cu3 |

| AlSi7Mg0.3 |

| AlSi12 |

| AlSi12 (Cu) |

| AlMg5Si1Mn |

| AlCu5NiCoMnSbZrTi (RR350) |

TECHNOLOGICAL EQUIPMENT

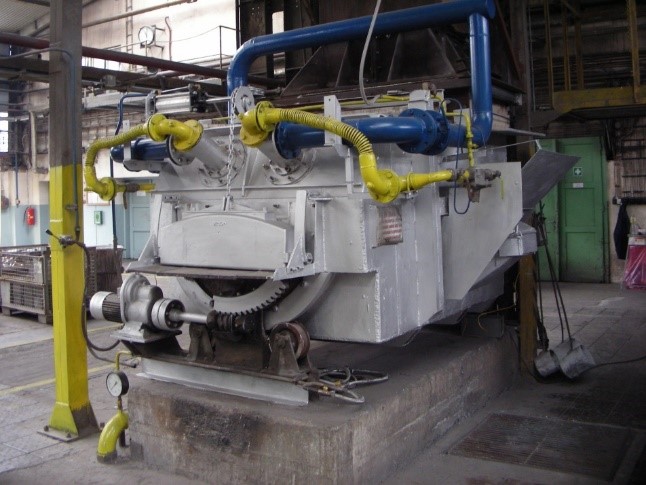

MELTING SHOP

We use four gas melting furnaces to produce liquid metal - two hearth furnaces of the Sklenár type with direct heating with a volume of 900 kg and two crucible melting furnaces with a volume of 600 kg and 1000 kg. For gravity die casting, we have 6 holding resistence crucibles with a capacity of 250 kg.

MOULDING SHOP

Moulding to sand

We produce moulds from a bentonite sand mixture on the new HSP-3 moulding machine from HWS - Sinto. The HSP-3 machine uses SEIATSU sand compaction technology. We also produce castings on two LSS 3R moulding machines by shaking and additional pressing. Machine forming allows us to achieve the accuracy of CT9 castings according to ISO 8062.

| Moulding line | Flask size (mm) | Number of flasks/Shift |

|---|---|---|

| HSP-3 | 1000x800x300 | 30 |

| LSS 3R | od 450x350x80 do 680x500x220 | 30 - 50 |

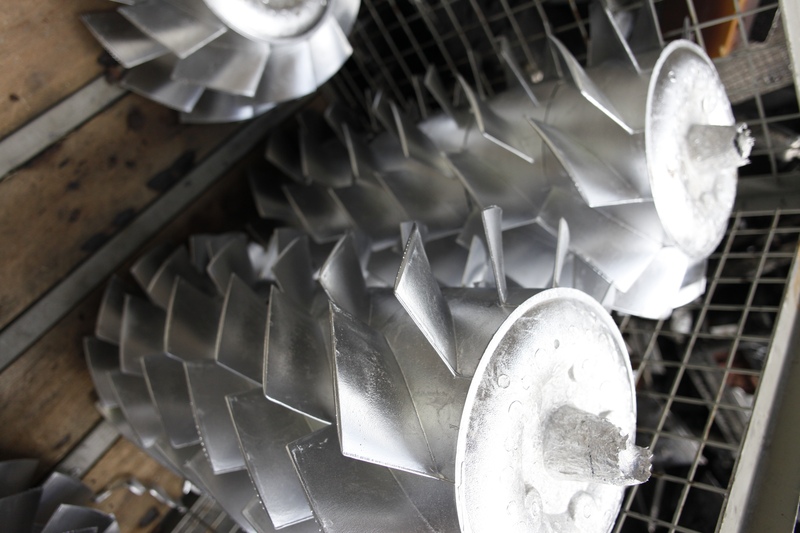

Gravity die casting

The gravity die casting shop has 6 casting machines of the EMBO type at its disposal. The casting stands are with hydraulic ejectors/pullers, opening on six sides. Die castings can be with or without a sand core. Casting accuracy is from CT8 to CT9 according to ISO 8062. Steel or brass castings can be cast into die castings. The maximum weight of die castings is 18 kg.

| Die machine | Number of castings/Shift |

|---|---|

| 6 x die machine of EMBOO type | 30 – 200 (depending on the weight of the casting) |

| 11 x die machine of CGH-08 type (with vertical dividing plane) | up to 200 |

| 1 x die machine of KG-222 type | up to 200 |

| 2 x special die machine for TATRA castings | up to 200 |

Hand moulding

We use manual moulding in case of piece production or production of large-sized castings that cannot be placed on machine moulding. The weight of the casting is limited by the size of the foundry ladle with a maximum of 250 kg of melt. The heaviest product was a casting with a gross weight of 149 kg and 11 cores. We achieve accuracy CT10 according to ISO 8062 for manual moulding.

| Flast size (mm) | Number of flasks/Shift |

|---|---|

| from 300x230x55 | 12 |

| max 1900x1000x300 | 3 |

max. 250 kg of melt

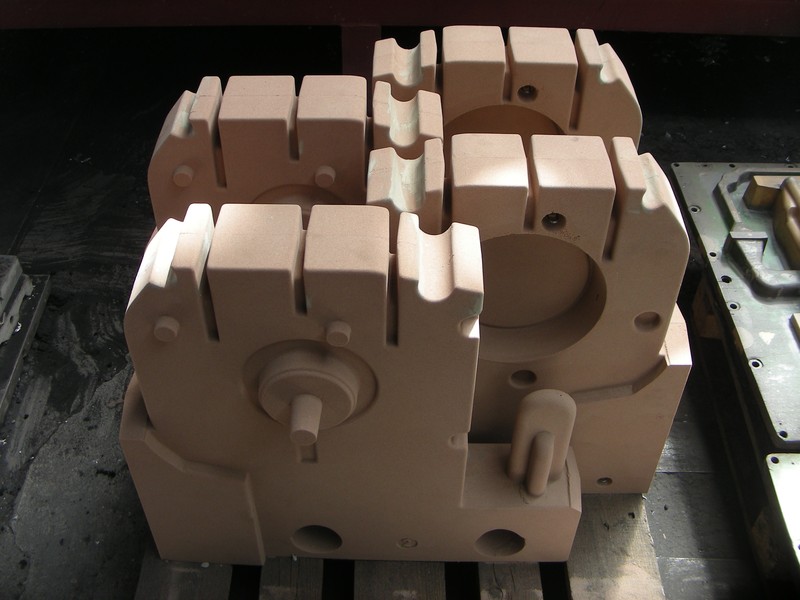

CORE SHOP

The aluminum foundry has its own core shop. There are three shooting machines at the core shop, where it is possible to produce cores weighing 0.1 kg to 45 kg using the COLD-BOX method. The other two machines are designed for the HOT-BOX method. At the workplace of manual forming of cores, we produce cores weighing up to 120 kg.

FINISHING OPERATIONS

Band saws are used to remove risers, exhausts and gate systems. The cores are hammered with a pneumatic hammer. Further finishing takes place on belt grinders, rotary files and using hand tools. Sand castings and some die castings are blasted with stainless steel shot in a DISA blasting machine.